Recovery problems with heap leaching

Heap leaching is a primary recovery process wherein metals are extracted by irrigating sizable stacks or heaps of previously crushed mineral ores with a combination of acids and water.

As the leaching fluid percolates through the heap, the metal is dissolved from the small concentration of minerals in which it is held up and is collected at the bottom.

There are well-known challenges in heap leaching and minerals extraction in general:

- the flow of the leaching solution in a heap is often unpredictable due to a combination of complex mineralogies, natural permeability barriers and excessive materials compaction;

- operators cannot see inside the heap and are blind to the presence of dry-zones or zones with excessive fluid accumulations, which leads to poor recoveries and increased the risk of slope collapse.

The solution

The Muon Vision platform continuously monitors the density of the heap and maps the distribution of the leaching fluid.

Our technology provides great benefits by:

- allowing to meet operational parameters;

- allowing to execute remedial actions when warranted.

Typically, leach operations target a fluid saturation “S” in the range between 10 and 20% of the total available porosity in the material.

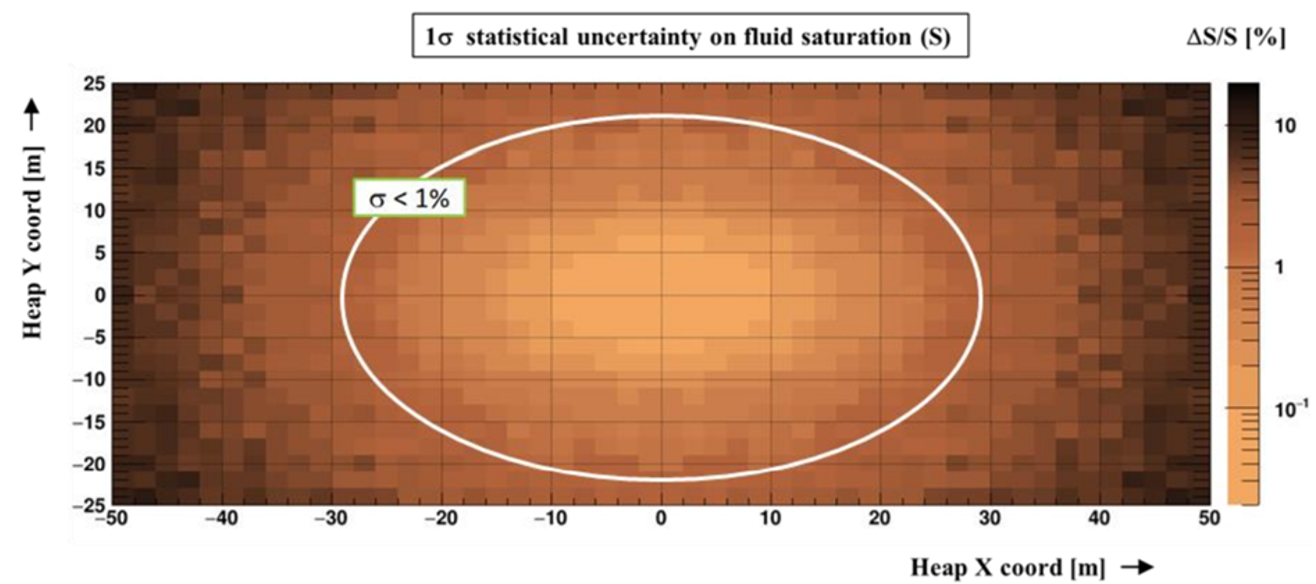

The projection below illustrates how a single Muon Vision sensor determines fluid saturation within a <1% uncertainty over a large area of the heap, subdivided in 2×2 m2 bins:

Muon Vision in heap leaching: extract more, pollute less

Heap leaching is less energy intensive than other metal recovery processes. This is critical in world of ever-shrinking ore grades. Yet, heap leaching still faces very high energy costs due to ore blasting, transport and crushing.

Not only that but, at the end of the day, metal recoveries are typically below 70% and the process mostly takes place unsupervised.

This is where we come in to help.

FAQ: how is the acid-containing fluid distributed inside a large heap ?

Muon measurements can be utilized to quantitively determine volumes of the acid-containing fluid (in liters, irrespective of ionic content) across the full asset in a reasonable observation time (7- 10 days) and with great sensitivity (<1% of the pore space).

Muon measurements provide asset managers with a new powerful tool for the optimization of irrigation patterns and agglomeration parameters; it also helps them verify and maintain targeted operational parameters.

FAQ: can we measure compaction?

Poor compaction is a leading cause of percolation issues. Muon-based bulk density measurements are a natural choice for validating the performance of stacker and heap construction operations prior to the start of irrigation.

FAQ: how does Muon Vision help raise the recovery factor?

The Muon Vision data platform is expected to increase mine throughput by illuminating by-passed pay and driving remedial actions. With our data, we expect mine operators will be able to increase their recovery factor by at least 10% .

FAQ: how does Muon Vision save equipment and protect staff?

The Muon Vision data platform will save expensive machinery and, most importantly, save lives.

Over-wet conditions in leaching heaps are a leading cause of slope collapse and potentially catastrophic failures. Furthermore, over-saturation can significantly slow down reclaim operations, and limit access or trap expensive equipment. Another important benefit of our technology is ensuring the stability of heaps and minimize non-productive time (NPT) against excessive fluid accumulations.

FAQ: How does Muon Vision help reduce a mine’s footprint?

The Muon Vision data platform significantly reduces the energy and water footprint required per tonne of produced metal.

A more efficient leaching process will save up to 600kg of CO2 and up to 4000l of water per tonne of copper.

For a large mine this is equivalent to reforesting an area of 530 km2 per year or to giving back the energy produced by 22 state-of-the-art windmills. It will also save water volumes such as to fill 2.4 class T1 super-tankers!